Project Focus

Delivering efficiencies by increasing degree of automation

Collaborative robotics

Machine learning and vision systems

Generating, classifying, and retrieving manufacturing data

Interoperability in context of Industry 4.0

Collaborators

Project Background

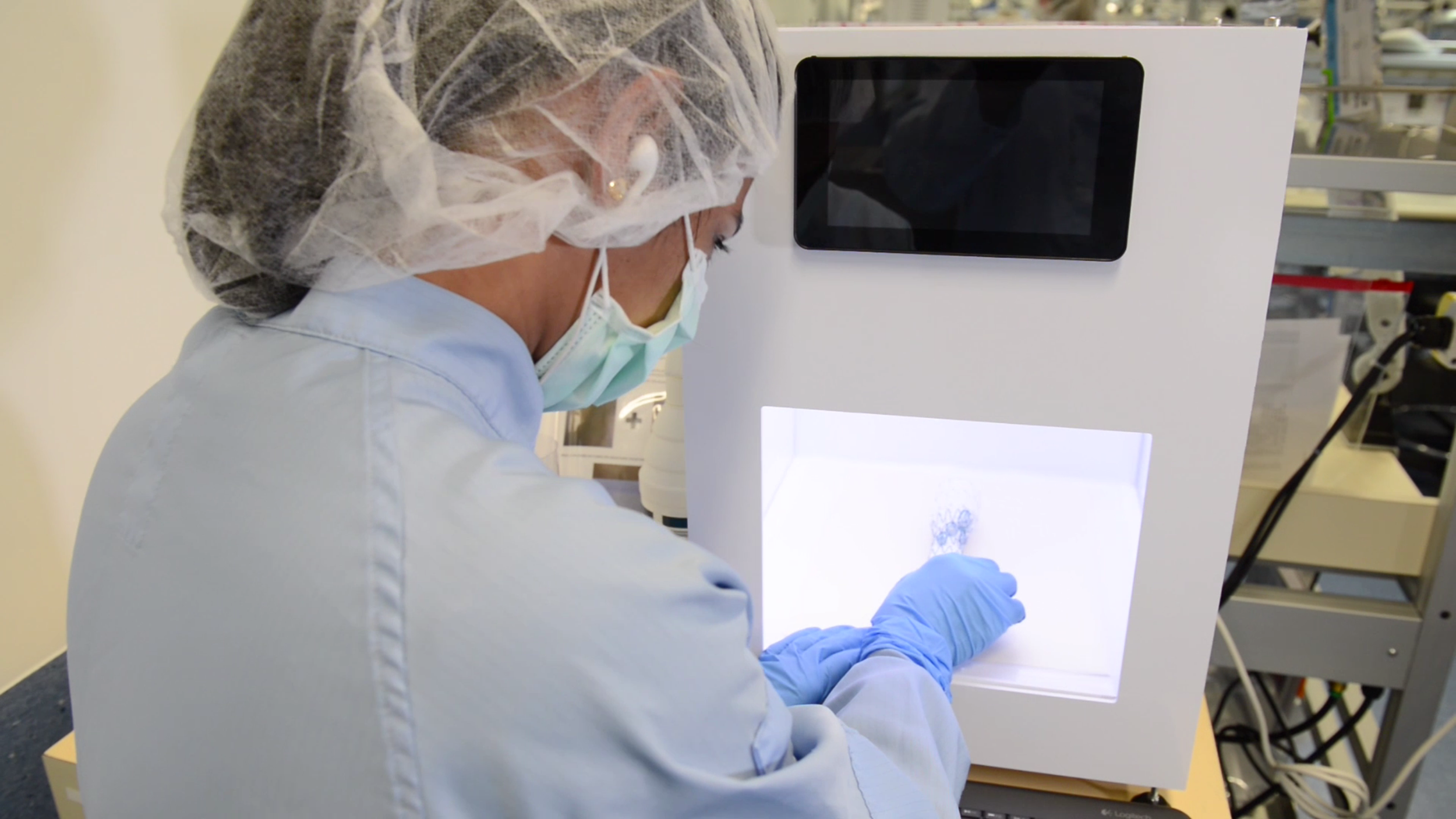

Automation solutions to solve product and information flow challenges associated with manufacturing customised medical devices are delivered, focused on specific hardware and software solutions. Collaborative robots, or cobots, can work directly with humans on a variety of flexible tasks, and matching the capabilities of the cobot with labour intensive tasks often associated with custom manufacturing can deliver significant cost savings and enable opportunities for business growth. However, manufacturers often face challenges such as difficulty in developing in-house skills in cobot manipulation, robotic vision, sensors and safety, as well as communicating with legacy machinery, leading to impeded uptake of this technology. One focus area is to identify and reduce barriers to entry for implementing collaborative robotics into existing manufacturing processes. Another example is an automated quality assurance system to identify defects under human supervision, using an image analysis algorithm.